These are some of the projects in which we have been proud to participate

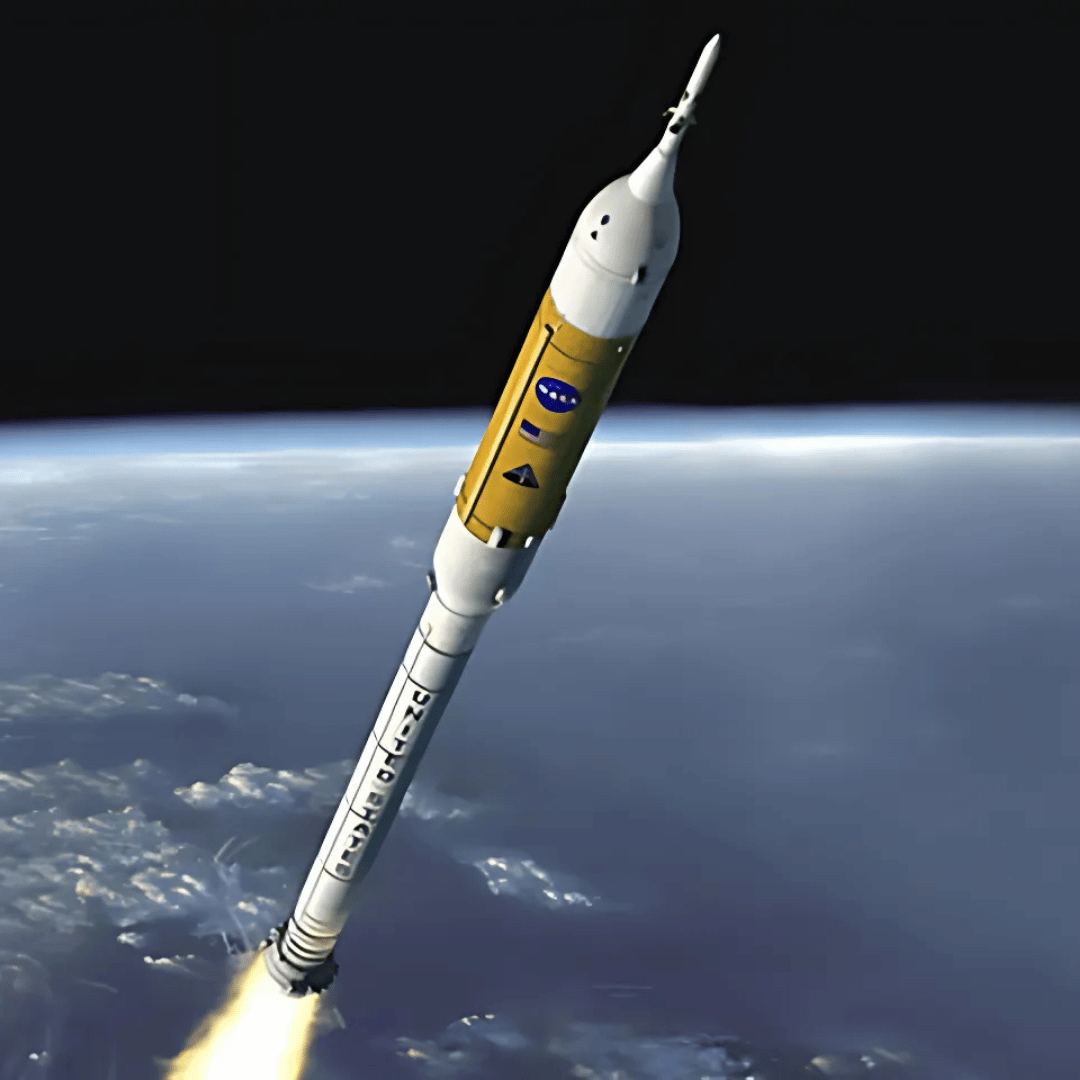

Orion Launch Abort System

NASA is one of the many prestigious clients that have depended on Rickard Metals for the procurement of engineered and finished products. For example, we were contracted to provide 6AL-4V-Eli Titanium forgings for the fabrication of the crew evacuation system for NASA’s Ares Orion rocket.

Often referred to as LAS (launch abort system) this escape mechanism on the Ares I will propel the Orion crew capsule clear of the rocket in the event of an Ares pad or launch malfunction. Click here for an animated view of the system at work

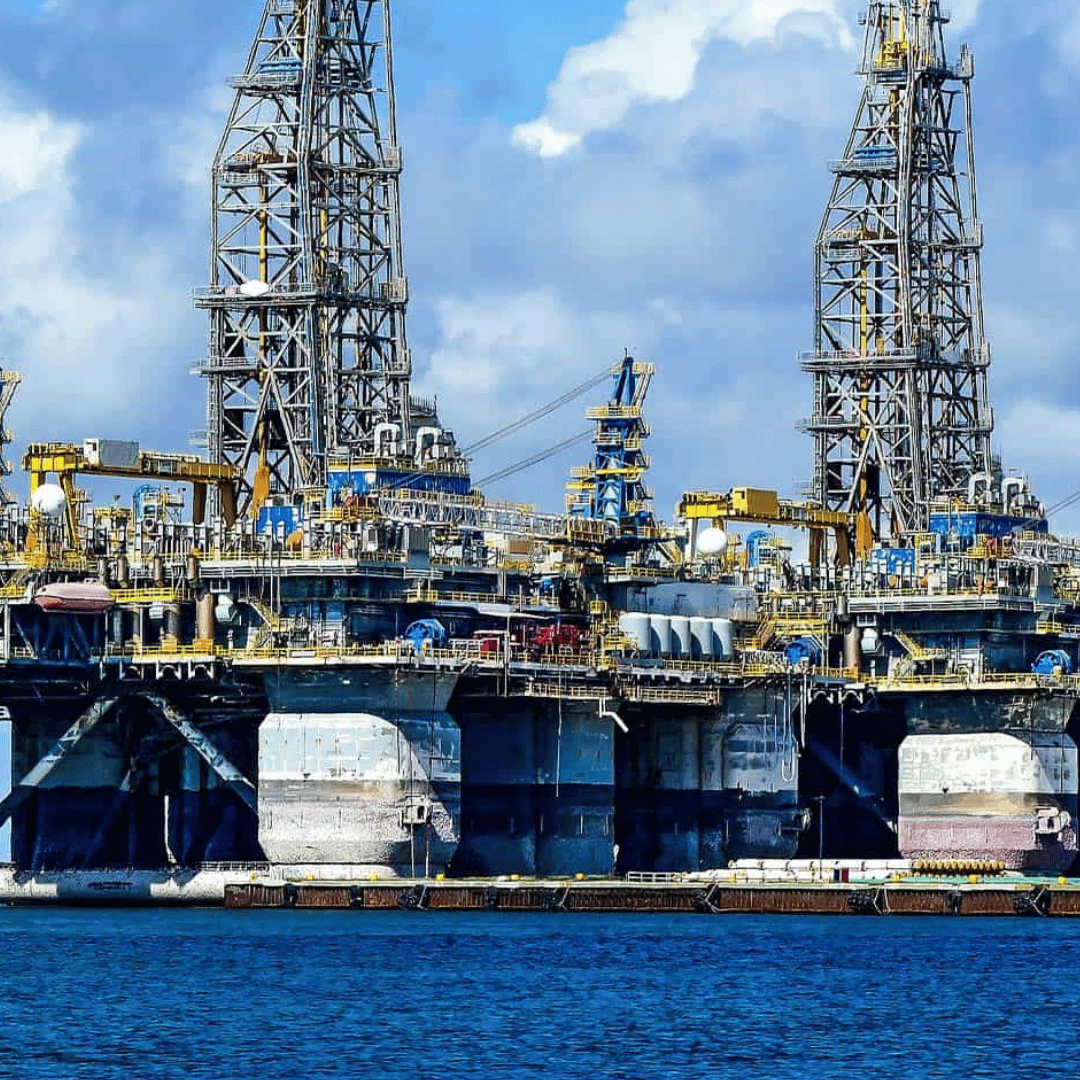

Offshore Oil Extraction Equipment

Rickard Metals’ projects can be found not only in space, but also in the deep, high-pressure regions of the world’s oceans. We have supplied 2,500 pound drill forgings produced from alloy steel for use in the petrochemical industry.

Often referred to as LAS (launch abort system) this escape mechanism on the Ares I will propel the Orion crew capsule clear of the rocket in the event of an Ares pad or launch malfunction. Click here for an animated view of the system at work

ISS Static Test Fixture

As an experienced aerospace vendor, we not only provided titanium forgings for the LAS for the Orion capsule, but we also fabricated the static test fixture for the International Space Station Node 2, aka Harmony.

The static testing of this module, which serves as the utility hub of the International Space Station, helps to ensure its continued quality and performance in its position on the forward end of the Destiny research station on the ISS.

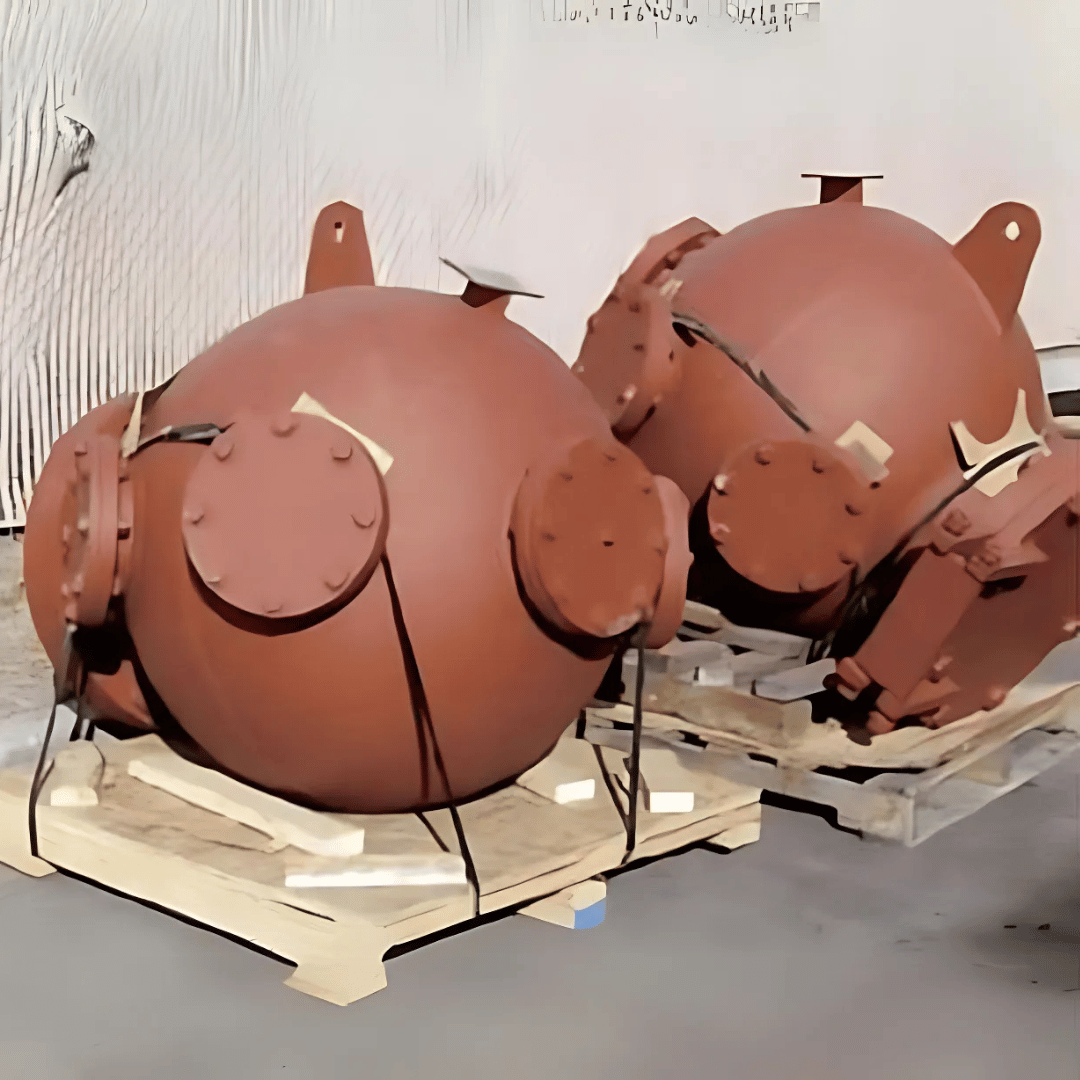

Naval High-Strength Pressure Vessels

This complex fabrication made primarily of steel was developed for the US Navy. We are very familiar with government contracts and their stringent requirements.

In addition to steels, we can supply titanium, aluminum, nickel-based superalloys and fracture critical alloys for specialized applications.

The static testing of this module, which serves as the utility hub of the International Space Station, helps to ensure its continued quality and performance in its position on the forward end of the Destiny research station on the ISS.

Boeing 787 Trailing Edge

The Boeing 787 is a wide-body jet airliner with a carrying capacity of 210 to 330 passengers. The Boeing 787 Dreamliner is widely known as the first airliner to be made primarily from composite materials, mainly carbon fiber reinforced plastic.

However, a lesser known fact about the 787 is that it also makes greater use of titanium than previous commercial aircraft (titanium used in the manufacturing of Boeing airliners is assigned a Boeing Material Specifications number, e.g. Titanium BMS 7-348).